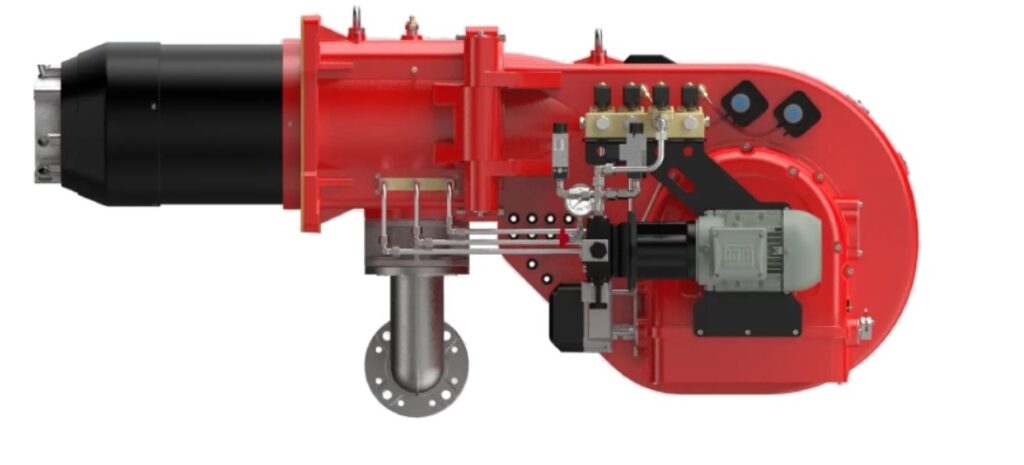

The PrecisionFlame NM Burners represent the latest in nozzle-mix combustion technology, offering exceptional efficiency and low emissions across various industrial applications. Designed to meet the demands of modern combustion systems, these burners ensure optimal air-fuel mixing for stable flames, improved performance, and reduced environmental impact.

Applications:

Hot Water and Steam Boilers

- Used in heating systems, sterilization processes, and power plants, ranging from single-burner units for small businesses to multi-burner systems for industrial plants.

Industrial Furnaces

- Perfect for metal treatment, glass melting, and ceramic kilns requiring precise temperature control and high thermal efficiency.

Drying and Heating Systems

- Ideal for processes that require consistent, controlled heat, such as food processing, textiles, and chemical production.

Why Choose PrecisionFlame NM Burners?

- Environmental Compliance: Meets BS EN 676 and BS EN 267 standards, achieving up to NOx Class 3 emission levels.

- Versatility: Suitable for a wide range of applications, from steam boilers to high-temperature industrial furnaces.

- Operational Efficiency: Reduces fuel waste and enhances system performance with uniform combustion.

- Innovative Design: Synchronizes gas outlet speed and airflow direction to ensure complete mixing and minimize emissions.

Features:

- Efficient Air-Fuel Mixing: Combines air and fuel at the nozzle using advanced turbulence and flow synchronization, ensuring complete combustion.

- Low Emissions: Incorporates technologies like Flue Gas Recirculation (FGR) and Low-NOx designs to minimize NOx, CO, and SOx emissions, meeting stringent environmental standards.

- Customizable Design: Adaptable to specific industrial needs, including furnace geometry and temperature requirements.

- High Reliability: Engineered for stable flame performance even under variable operating conditions.